Gas chromatography is a process used to separate chemical

compounds for analysis. The analytical chemistry process is used with gases

that won't decompose when vaporized. Gas chromatography are used in a wide

range of industries -- everything from forensic science to medical marijuana.

While the procedure is highly useful, there are risks when working with

nitrogen gas. Learn how gas chromatography works, the role nitrogen plays, and

how an oxygen sensor improves safety.

How

Gas Chromatography Work

In chromatography, one gas moves over the sample substance. The

moving gas is known as the mobile phase, and it's usually an inert gas, such as

nitrogen or helium. As the mobile phase passes over the substance, it separates

out into its component parts. Since accuracy is key, it's vital that the moving

gas not react with the substance being analyzed. For this reason, inert gases

are recommended for gas chromatography.

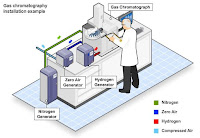

Gas chromatography takes place within a special machine, known

as a gas chromatograph machine. The substance being studied is injected

into the chromatograph with a syringe, then the material is heated to the vapor

stage. The carrier gas -- e.g. nitrogen -- is then added to the chromatograph

to push the sample up the central column. As the substance being analyzed

passes up the column, it's absorbed by the carrier and then separated into its

distinct components. The components emerge from the column and pass through a

detector, where they are identified and noted on a chart.

When the process is complete, every part of the mixture is

identified. At this point, for instance, a forensic scientist will have

the raw data needed to analyze evidence found at the crime scene. While

television shows may portray the process as instant, it's often time-consuming.

Within the medical marijuana industry, scientists are using gas

chromatography to test for pesticide residue in cannabis. While the medical

marijuana industry is still young, and pesticide levels are not heavily

regulated, industry leaders expect this to change as the marijuana industry

grows. Thus, the use of gas chromatography to check for pesticides will grow

too.

Whenever gases is used in the chromatography

process, there's a potential for gas leaks, whether from the supply lines,

storage tanks, or from the chromatograph itself. Nitrogen gas displaces oxygen.

If nitrogen were to leak, air levels would become deficient of oxygen and

employees could suffer health problems.

Since nitrogen gas has no color or odor, there is no way for lab

staff to tell that the gas has leaked. The best way to safeguard the lab is

with an oxygen monitor.

How

an Oxygen Deficiency Monitor Protects Employees

Risks of breathing oxygen deficient air include dizziness,

fatigue, unconsciousness, and death via asphyxiation. All it takes is a couple

breaths of air to experience adverse health effects.

Since there is no way to tell whether a leak has occurred, it's

necessary to use an oxygen sensor to track oxygen levels at all times. The

oxygen monitor or sensor measures oxygen and only reacts when levels fall below

a predefined threshold. Oxygen sensors from PureAire have alarms for

oxygen levels of 18 percent and 19.5 percent, for instance.

The oxygen deficiency monitor includes a flashing light and loud

alarm, so that staff and passerby receive prompt notification of the leak. When

the alarm goes off, employees can vacate the premises and contact emergency

personnel.

Given the serious risks posed by a nitrogen gas leak, it's

important to use oxygen deficiency monitors anywhere inert gases are stored or

used.

PureAire is an industry leader when it comes to oxygen

monitors. O2 monitors from PureAire are designed for

long-lasting and maintenance-free use. They feature a zirconium sensor, which

lasts for 10-plus years without calibration. PureAire's monitors can

handle temperature changes, barometric shifts, and even freezing

temperatures. Learn more about PureAire's monitors and how they

promote safety at

No comments:

Post a Comment