While cryotherapy or frost therapy has been used for

millennia, the new cryotherapy center

fad that's become popular in salon culture has come under scrutiny when a

24-year-old woman who worked at a cryohealth center in Las Vegas was

found dead after using a cryo chamber at work. Learn more

about cryotherapy, what it claims to do for the

body, and whether or not it can be safely used.

The

Health Benefits of Cryotherapy

Advocates

claim that there are many benefits of cryotherapy and

that the treatment is highly safe when it is properly performed. The type of

whole body cryotherapy in

use at cryohealth centers

today was developed in 1978 as a rheumatoid arthritis treatment. While

this treatment is often covered by health insurance in other nations, the

U.S.healthcare industry does not recognize cryotherapy for

insurance purposes or much regulate the field.

Unlike

immersion in an ice bath, the chill of cryotherapy is

dry so it does not feel uncomfortable, like submersion in an ice bath would.

Exposure to chilled air can treat sports injuries, muscle soreness, joint pain,

pain and inflammation associated with health conditions like arthritis or

fibromyalgia, and immune function. Some even claim that cryotherapy can help with weight loss or delay the

aging process.

Is Cryotherapy Safe?

Individuals

with certain health conditions -- including hypertension, heart disease,

seizures, anemia, pregnancy, and claustrophobia -- should not use cryotherapy.

For other individuals, cryotherapy has

generally been considered safe. Some individuals may experience redness or skin

irritation, an allergic reaction to the cold, frostbite, or skin burns.

If

the individual stays in the cryotherapy chamber

longer than recommended, or the facility does not take the proper precautions,

health risks increase. Typically, people are only supposed to expose themselves

to the cold temperatures in the cryo chamber

for two to three minutes. The salon where the woman died was apparently selling

30-minute sessions, the New York Post reports. 30 minutes is too long to spend

in frigid temperatures.

In

the case of the employee who died in a cryotherapy chamber,

no one apparently knew the woman was in there since she went in alone after

work. Most cryotherapy chambers

only allow people to use the facility when someone is onsite monitoring them as

a first line safety precaution.

Even

if the employee did not follow proper procedures in entering the cryo chamber, her death raised awareness of

hidden dangers in this unregulated industry. People want to know whether this

popular treatment is safe for them. The salon where the woman died was not

licensed with the State of Nevada.

Safety

Measures for Cryotherapy

Cryotherapy can be safe when performed by a

licensed facility that has safeguards in place to make sure that those

undergoing treatment do not stay in too long, do not get overlooked, and are

not exposed to environmental hazards.

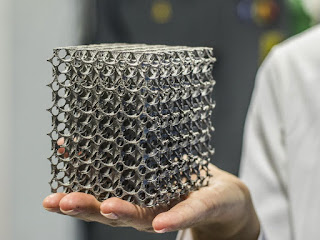

One

reliable way to monitor the environment of the cryo chamber is to use an oxygen monitor or

oxygen deficiency monitor. An oxygen deficiency monitor continuously measures

the amount of oxygen in the environment and sets off an alarm if

oxygen falls below a safe level.

Cryohealth

chambers use a form of nitrogen to create a dry frost and chill the chamber.

Nitrogen, when used in high doses, creates an oxygen deficient environment. In

a worst-case scenario, the room could become so oxygen deficient that anyone

inside could suffocate to death.

Since

nitrogen does not have an odor or a color, individuals cannot see it. When a cryohealth chamber is equipped with an

oxygen monitor, the air inside will not fall below safe levels without

first alerting staff to the drop in oxygen. Staff can then assist any patients

in evacuating the cryotherapy chamber

before something bad happens.

PureAire

offers O2 monitors

that are made with zirconium sensors, which are guaranteed to last for at least

10 years and hold up equally well in humid and dry environments. Once the

facility sets up O2 monitors

in every cryo chamber,

staff can rest assured that the monitors will alert them to any sudden change

in oxygen levels with enough time to get people outside of the chamber before

something bad happens.

When

a facility uses oxygen monitors inside the chambers, has a license from the

State, and ensures that staff monitor the chambers during treatments, cryotherapy can be performed safely.

To

learn more about PureAire's line of oxygen deficiency monitors, visit

www.pureairemonitoring.com.